How important is the "localization" of industrial software? We have a deep feeling again in the recent big events.

The recently issued "Several Measures to Promote the High-quality Development of Software Industry in Shenzhen" also clearly pointed out that it is necessary to actively promote the high-quality development of software industry and "gather strength to attack core software".

As the mother of electronic products, PCB plays an important role in the manufacturing industry. As the core software in PCB manufacturing, PCB CAM software is widely used in various processes of PCB production, such as: production feasibility analysis, design data conversion and refinement processing, and providing production data (film, drill tape, gong tape, etc.) for each process.

However, a cruel reality is that such important industrial software has been monopolized by foreign countries for a long time, and the application ratio of foreign software such as Genesis2000, UCAM and CAM350 has reached more than 95%. In the complex international environment, "domestic substitution" is urgent!

How to build a PCB CAM industrial software with perfect functions and independent intellectual property rights? Perhaps, we can find the answer from the PCB CAM software recently launched by Jialichuang.

The key to "domestic substitution" needs a mature and easy-to-use software product.

As we all know, the replacement cost of industrial software is very high. In order to realize "domestic substitution" of PCB CAM software, the author believes that three basic conditions need to be met. First, the performance of the product should be strong and stable enough for CAM engineers and manufacturers to use it.

CAM software almost runs through the whole process of PCB production, which can be divided into three stages: one is the pre-production order quotation stage, and the production feasibility is analyzed and quoted through Gerber view and DFM function; The second is the engineering data processing stage, which transforms the customer’s design data into production data, and edits and modifies the design that may lead to bad, so as to improve the production yield; Third, in the manufacturing stage, because many different equipments will be used in each production process, it is necessary for CAM software to convert and be compatible with Gerber files, such as converting them into data formats required by LDI, drilling, milling and testing equipment, before production can be carried out.

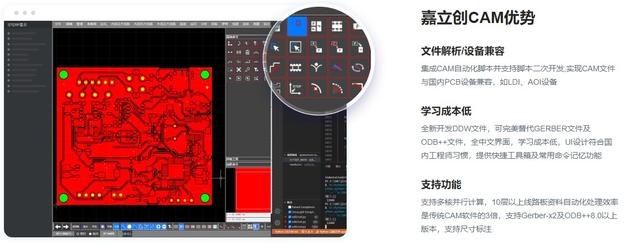

Jialichuang’s recently launched industrial basic software-Jialichuang PCB CAM software just fills the gap in this field in China, which can be applied to the whole process of PCB manufacturing.

The author understands that Jialichuang’s PCB CAM software has been polished within its group for nearly ten years, and its stability and performance have been fully verified.

The second is the difficulty of operation. It is reported that Jialichuang CAM software is specially developed for domestic users and can meet the needs of domestic manufacturers. The all-Chinese operation interface is simple and easy to use, so users don’t have to worry about language problems. In addition, they also have a professional team to provide technical support. Compared with foreign software, the use threshold of this software is greatly reduced.

Finally, it is open. Tested by the author, this software supports Gerber, Gerber274X, PDF, DXF and other data formats, and has extremely powerful graphic editing function and analysis and inspection function. More crucially, the software allows users to carry out the secondary development of scripts, has good flexibility and expansibility, and can achieve a high degree of adaptation between the software and production equipment, processes and operators.

In the field of PCB CAM software monopolized by foreign countries all the year round, it is not easy to have such a domestic software with perfect functions to "break through".

From EDA to CAM software, why can Jialichuang write the story of "domestic substitution" again?

Years of industry accumulation provide rich soil for breeding industrial software.

Industrial software is related to the core competitiveness and systematic safety of China’s industrial chain, and it is a very difficult link. Excessive dependence on foreign software will not only lose the software market, but also face the risk of losing the initiative of industrial development and affecting the security of industrial information. The development of an industrial software requires the accumulation of technology and experience, but also takes time to verify, "fast is impossible."

Developing industrial software requires a strong industrial foundation. It has been 16 years since Jialichuang was established in 2006, and it is well-known in the industry. The main business covers the electronic and mechanical fields such as EDA software, PCB intelligent manufacturing, component mall, laser steel mesh, SMT patch and FA mechanical parts mall. Among them, PCB intelligent manufacturing includes various types such as large batch, small and medium batch and proofing, with tens of thousands of daily orders, and all orders adhere to self-operated manufacturing.

A large number of production requirements have prompted Jialichuang to build its own PCB CAM software. As early as ten years ago, they started layout and exploration. Orders and equipment of sufficient magnitude are also repeatedly verifying the reliability and stability of this software, and can update iterations in time according to the latest changes and production requirements of the domestic PCB industry. "The number of iterations of this software update is so much that we can’t remember it ourselves." The person in charge of Jialichuang CAM software said.

If the scale is huge and the orders are complete, it is the fertile ground for Jialichuang to cultivate PCB CAM software; Then, the supply of professionals is the "nectar" of the growth of this software. Independent research and development of industrial software requires professionals who know not only production and equipment, but also software, technology and algorithms, and such talents are rare.

Jialichuang’s current R&D team has more than 400 professionals, which provides a solid support for the development of industrial software. "A R&D team with professional talents, after ten years of polishing, has this mature product that can compete with foreign PCB industrial-grade CAM software."

The birth of an industrial software takes a lot of time and practice.

Sharing high-quality resources to ensure that the key links in PCB industry are self-controlled

Ni Guangnan, an academician of China Academy of Engineering, once publicly stated: "We are going to move from a manufacturing power to a manufacturing power. Without the support of industrial software, the transformation, upgrading and further development of traditional industries will face great problems."

For PCB manufacturers, foreign PCB CAM industrial software is expensive, with hundreds of thousands at every turn; Pirated software not only cannot realize customized design and secondary development of scripts, but also faces great legal risks. In recent years, the phenomenon of scientific and technological repression and blockade has constantly appeared in the international community, which has sounded the alarm for us: any link that cannot be guaranteed to be self-controlled will become the weakness of attack, and it is urgent to realize the "domestic substitution" of industrial software.

The person in charge of Jialichuang CAM software said frankly: "We decided to open this software to the public for free or at a very low price. First, we hope that China circuit board manufacturing enterprises can have independent and controllable software and have enough confidence to cope with the uncertainty of the external environment; The second is to contribute to the upgrading of industrial chain and the reconstruction of value chain made in China. "

It can be predicted that the transformation and upgrading of China’s manufacturing industry and the development of industrial software coexist and are inseparable. On the one hand, the stronger the manufacturing industry is, the more important the industrial software is, which will inevitably lead to more localized and fully functional products to meet the needs of domestic enterprises for low cost, high efficiency and flexibility, and get rid of the "stuck neck" dilemma. On the other hand, mature industrial software will also feed back China’s manufacturing industry, accelerate the process of digital and intelligent transformation of domestic industries, and promote the high-quality development of "China Zhizao".

Disclaimer: The market is risky, so you should be careful when choosing! This article is for reference only, not as a basis for trading.